Digging starts on new artery between Xuhui and Minhang

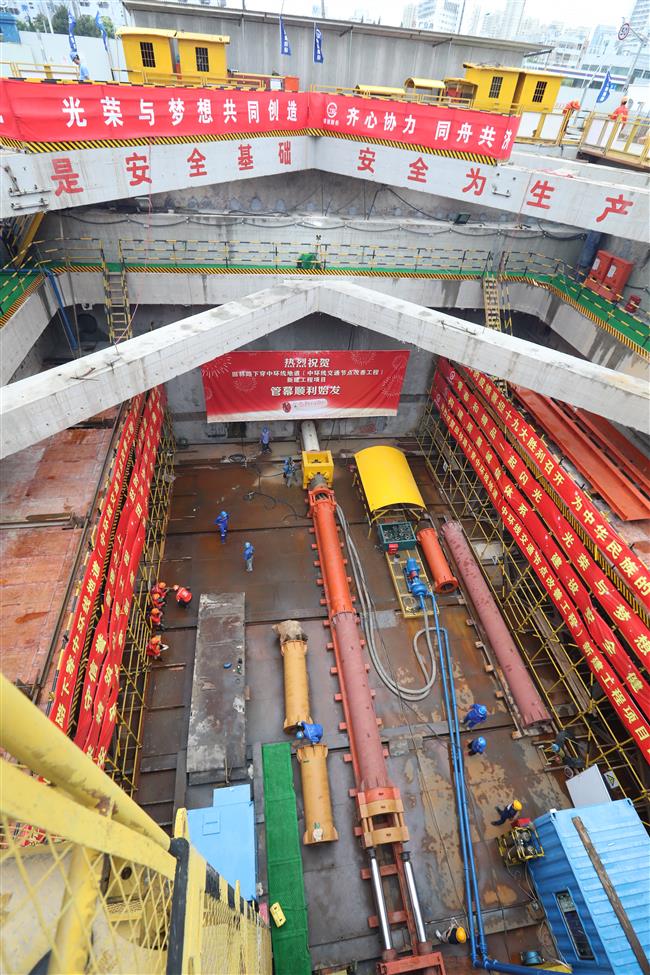

The first hollow steel tube with a diameter of 80 centimeters is being pumped into the soil beneath the ring road in an innovative digging method to prevent land subsidence as well as to reduce vibration and noise.

Digging started over the weekend for a tunnel to connect Xuhui and Minhang as well as to ease traffic congestion in the Caohejing area.

The 1-kilometer-long tunnel on Tianlin Road will be a major artery between Xuhui and Minhang districts when it is completed at the end of 2018, according to its manufacturer, the STEC Shanghai Urban Construction Municipal Engineering Group.

The tunnel, including an 86-meter section beneath the Middle Ring Road, will have three vehicle lanes and two bicycle lanes. It has a designed speed of 40 kilometers per hour for vehicles.

Drivers and pedestrians on Tianlin Road currently have to detour to parallel streets because the ring road cuts the road off, causing congestion, especially during rush hours. A large number of vehicles are jammed on the nearby Yishan and Caobao roads during the morning and evening peak times every day, according to the traffic police.

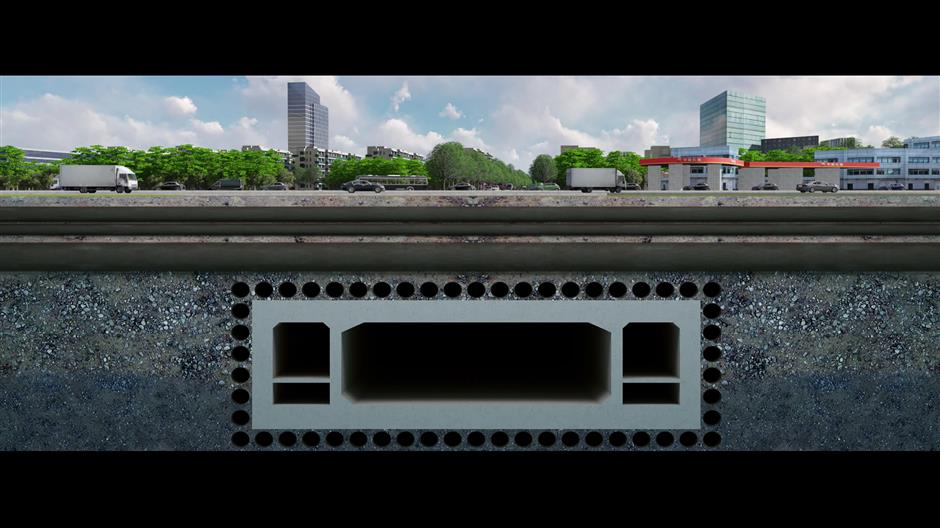

An artistic rendition of Tianlin Road Tunnel, which is due to be completed by the end of 2018.

A major challenge of the project is that workers have to dig beneath the busy ring road without affecting its operation, said Zhang Zhen, the project manager.

The first hollow steel tube with a diameter of 80 centimeters was pumped into the soil beneath the ring road on Friday, an innovative digging method to prevent land subsidence as well as to reduce vibration and noise.

Comparing with the traditional digging by a shield, the “tube pumping” method can also shorten the schedule by 30 percent, Zhang said.

Under the method, workers keep pumping a total 62 steel tubes into the soil under the ring road to cut a rectangle shape 20 meters wide and 6 meters high. A box-culvert will then dig out the soil within the rectangle to build the tunnel, said Liu Yuhong, the technical supervisor for the project.

Workers pump steel tubes into the soil under the ring road. A total 62 such tubes will be pumped into the soil to cut a rectangle shape 20 meters wide and 6 meters high.

A worker monitors the pumping process to ensure accuracy and prevent land subsidence.

The technique will be applied to other tunnel and subway constructions in future, Liu said.

An artistic illustration of the "steel tube and box-culvert" digging method.